Markets

Defense & Aerospace

When everything is on the line, there is no room for error. The microelectronics that power mission critical platforms must meet exacting testing, qualification and reliability standards. Unlike other chip makers that continuously discontinue the chips you have come to rely on, Phoenix was designed for the low volume, high mix demand from Defense and Aerospace markets.

Chip Obsolescence Threatens our National Security and Defense Readiness

Traditional chip makers operate on a 12-month design cycle and at huge volumes, leaving behind the defense industry that has longer development cycles and lower volume demand for replacement parts.

Obsolete Before Fielding

By the time a platform is ready for the field many of the electronic components have already been discontinued. This leaves defense programs vulnerable to supply chain disruption and future sustainment challenges.

Budget and Time Overruns

When components aren’t available, board redesigns are often the only viable option for this market. On average this can cost a program $2M and 2 years of additional time.

THE PHOENIX DIFFERENCE

Keep Platforms Running Longer

Phoenix drop-in replacements help keep mission critical platforms up and running without having to stockpile chips, buy from brokers or redesign boards.

Low Volume, High Mix

Traditional chip manufacturers aren’t able to keep their production lines operational once demand falls. Phoenix was built specifically to address the low volume and high mix of parts that defense and aerospace companies demand.

Months, Not Years

Until now, recreating an obsolete chip involves a fab, new silicon and running a production line. Not only does this cost millions of dollars, it also takes years to get a new chip made. Phoenix’s innovative approach cuts production time from years to months. Have the replacement part up and running in your platform on your time frame.

Redirect Resources for Bigger Impact

Estimates show that 80 cents of every dollar spent on defense platforms goes to sustainment activities instead of directly supporting the nation’s war fighters. Phoenix is unlocking new options for defense and aerospace industries that will decrease the cost of sustainment.

70%

of microchips in new military systems are discontinued prior to first deployment

$2.3M

The average cost to redesign a system-level board within a platform

2 Years

Average time to resolve and redesign a system-level board

The Phoenix replacement chips passed CCA and system-level testing the first time, which will save us millions in redesign costs. I only wish this solution was available sooner.

Product Director

Defense Prime Contractor

Resources

Insights on Defense Tech

Explore the latest in defense and aerospace innovations.

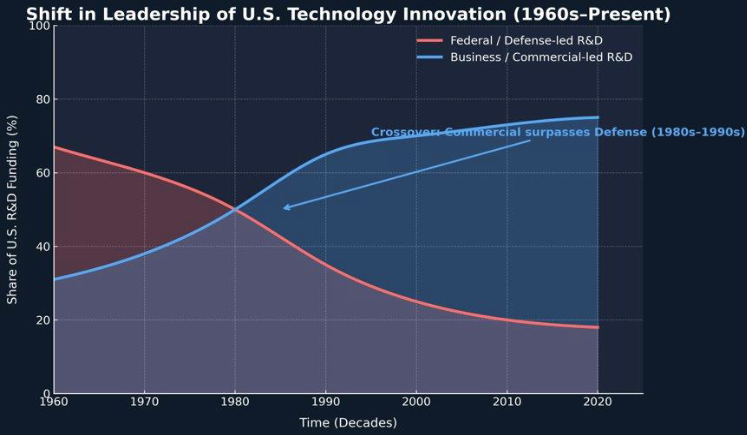

Who Drives Tech Innovation and Who Gets Left Behind?

From the 1950s through the 1970s, the U.S. federal government led the charge in technology innovation, driven largely by defense-funded R&D. But by the 1980s,…

Keeping 100-Year-Old Platforms Performing

The B-52 Bomber is still flying missions. That’s not a typo, and you didn’t just get transported back to WW2. In fact, the Air Force…

Explore our product catalog

and order samples

Phoenix has partnered with AVNET to provide our customers with an effortless ordering process and a trusted distribution partner.